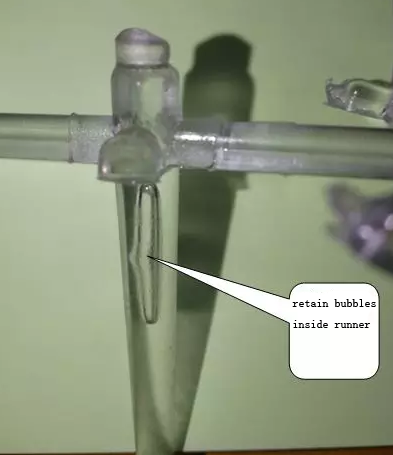

poly-carbonate injection molding voids inside runner

It is not uncommon for poly-carbonate injection molding applications to experience voids. These air pockets are most evident in the case of transparent materials, but they can also appear in the case of colored or opaque materials.

When a thick PC part surface solidifies faster than the inside, a void will often appear as a result of the outside layer of the part cooling off and solidifying faster than the inside.

When a void is discovered, there are a number of factors that can come into play, and they could be caused by the machine (process), the mold, or the material itself.

Void defects are most often caused by process errors, and you can make some adjustments to lessen your risk of void defects. In general, increasing the shot volume, injecting more pressure, increasing the screw forward time, or reducing the melt temperature is likely to do the trick.

It is also possible that mold is responsible for the void. If so, these are areas worth considering.

How large should the gate be for the part?

Where should the gate be located?

Is the runner sized or designed incorrectly?

The mold temperature could also be too low or inadequate ventilation could be present.

The material should be taken into consideration as well. Moist materials may cause voids. The material may need to be dried for an extended period of time to remove all excess moisture if this is the case.